-

De machine van de zakkenverpakking

-

De Machine van de korrelverpakking

-

vloeibare verpakkingsmachine

-

de machine van de poederverpakking

-

Mini Doypack Packaging Machine

-

De machine van de theezakjeverpakking

-

de machine van de koffieverpakking

-

verticale verpakkingsmachine

-

De Machine van de stroomverpakking

-

Tribune op Zak Verpakkende Machine

-

Roterende Vacuüm Verpakkende Machine

-

Het vullen Machine

-

Horizontale Doypack-Verpakkingsmachine

-

Premadezak

-

De Toebehoren van de verpakkingsmachine

-

vulmachine en cappingmachine

Automatische verpakkingsmachine voor wattenstaafjes: automatisch tellen, transporteren, voeden, in zakken doen en sealen

| Plaats van herkomst | Guangdong, China |

|---|---|

| Merknaam | ZCHONE PACK |

| Certificering | ISO,CE |

| Modelnummer | ZC-8200 |

| Min. bestelaantal | 1SET |

| Prijs | $18000 |

| Verpakking Details | Standaard exporteren houten kastverpakking |

| Levertijd | 15 |

| Betalingscondities | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Levering vermogen | 1/sets/15 dagen |

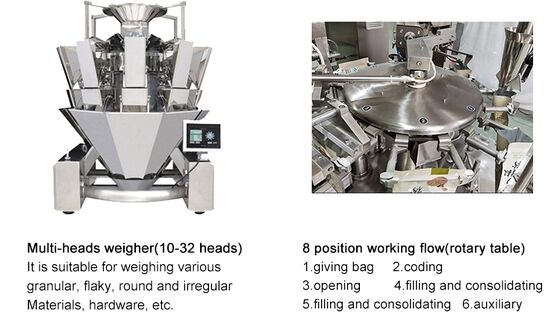

| Type | automatische verpakkingsmachine | Productnaam | Voedselgranule Multi-stations verpakkingsmachine |

|---|---|---|---|

| afmeting (l*b*h) | L1900*W1400*H1450 | gewicht (kg) | 1300 |

| Spanning | 110V 220V 380V 50Hz/60Hz | Productiecapaciteit | 20 zak/min, 50 zak/min, 30 tassen/min |

| Type verpakkingsmachine | |

|---|---|

| Verpakkingsmachine voor korrels | |

| Vloeistofverpakkingsmachine | |

| Poeder verpakkingsmachine | |

| Verpakkingsmachine voor opstaande zakken | |

| Verticale verpakkingsmachine | |

| horizontale verpakkingsmachine | |

| Teesakmachine | |

| Verpakkingsmachine voor koffiebonen | |

| horizontale verpakkingsmachine |

Automatische verpakkingsmachine voor wattenstaafjes: automatisch tellen, transporteren, voeden, verpakken en sealen

Een verpakkingsmachine voor wattenstaafjes is een volledig automatische of semi-automatische gespecialiseerde machine die wordt gebruikt om bulk steriele wattenstaafjes te verpakken in voorgevormde papieren-plastic zakken of composiet filmzakken volgens een vastgestelde hoeveelheid (bijv. 5, 10, 20 wattenstaafjes, enz.) en deze te sealen.

I. Belangrijkste typen apparatuur

1. Volautomatische verpakkingsmachine voor wattenstaafjes

Kenmerken: Volledig geautomatiseerd proces van het voeden van wattenstaafjes, tellen, verpakken tot sealen, zakken snijden en uitvoer van eindproducten; hoge snelheid, hoge efficiëntie en lage manuele arbeidseisen.

Capaciteit: Typisch 50-120 zakken per minuut of hoger.

Toepassingen: Grote fabrikanten van wattenstaafjes, bedrijven in medische hulpmiddelen; geschikt voor grootschalige gestandaardiseerde productie.

2. Semi-automatische verpakkingsmachine voor wattenstaafjes

Kenmerken: Vereist meestal handmatige plaatsing van wattenstaafjes in een trilhopper of teltank; de machine voltooit automatisch het verpakken, sealen en snijden. Relatief eenvoudige structuur en lagere prijs.

Productiecapaciteit: Afhankelijk van de handmatige voedingssnelheid, typisch 20-60 zakken per minuut.

Geschikt voor: Kleine en middelgrote fabrikanten, startups of voor kleine batches, productie met meerdere specificaties.

II. Standaard workflow (als voorbeeld een volautomatische machine)

1. Voeden: Bulk wattenstaafjes worden in een lift of trilhopper gegoten.

2. Rangschikken en tellen:

Trilplaat/baan: Trillingen rangschikken de ongeordende wattenstaafjes op een ordelijke manier en transporteren ze naar het telapparaat.

Tellen: Nauwkeurig tellen wordt uitgevoerd met behulp van foto-elektrische sensoren, mechanische klemmen of een visionsysteem. Dit is de kern van de machine en vereist extreem hoge nauwkeurigheid.

3. Verpakken: Een robotarm of duwer duwt een vastgesteld aantal wattenstaafjes in voorgevormde verpakkingszakken. De verpakkingszakken worden ter plaatse gevormd door een zakkenmaker met behulp van rolfilm, of voorgevormde zakken worden gebruikt.

4. Sealen:

Voor papieren-plastic zakken (één kant papier, één kant transparante composietfilm) wordt heat sealing gebruikt.

Voor volledig plastic composietfilm wordt heat sealing of pulse sealing gebruikt.

Sealen vereist een strakke afdichting, een glad oppervlak en een intacte steriele barrière.

5. Snijden en uitvoer: De continu gesealde zakken worden in afzonderlijke producten gesneden en via een transportband uitgevoerd, mogelijk aangesloten op een automatische codeermachine of etiketteermachine.

6. Optionele extra functies: Datum- en batchnummerafdruk (inkjet codering), gemakkelijk te scheuren opening creëren, tellen van eindproducten, afkeur van defecte producten, etc.

III. Kernstructuur en technische punten van de apparatuur

1. Telsysteem: De sleutel tot verpakkingsnauwkeurigheid. Geavanceerde apparatuur maakt gebruik van multi-level telverificatie (bijv. initiële telling + herinspectie) of machine visionsystemen om 100% nauwkeurigheid te garanderen.

2. Zakken maken en voedingssysteem:

Rolfilmtype: Gebruikt rolverpakkingsfilm voor het ter plaatse maken van zakken, lage kosten, hoge efficiëntie, maar vereist debuggen.

Voorgevormd zaktype: Gebruikt voorgedrukte individuele zakken, gemakkelijk van formaat te veranderen, esthetisch aantrekkelijkere verpakking, maar hogere zakkenkosten.

3. Transmissie- en controlesysteem:

Kern: Gebruikt typisch een PLC (Programmable Logic Controller) + touchscreen human-machine interface.

Aandrijving: Servomotoren en stappenmotoren zorgen voor precieze en gesynchroniseerde bewegingen.

4. Materialen en hygiënenormen:

Onderdelen die in contact komen met het product moeten zijn gemaakt van 304 of 316 roestvrij staal, voldoen aan de GMP (Good Manufacturing Practice) eisen.

Gemakkelijk schoon te maken, zonder onhygiënische hoeken.

IV. Ontwikkelingstrends

1. Intelligentisering: Integratie van meer sensoren en visuele inspectiesystemen om automatische monitoring, gegevensregistratie (aangesloten op MES-systemen), foutdiagnose en automatische afkeur van defecte producten te bereiken.

2. Flexibiliteit: In staat om snel mallen en parameters te veranderen om zich aan te passen aan verschillende lengtes, hoeveelheden en zaktypen wattenstaafjes.

3. Aseptische garantie: Voor medische wattenstaafjes heeft het ontwerp van de apparatuur prioriteit voor reinheid en kan worden gebruikt in cleanrooms of worden geïntegreerd met online sterilisatieprocessen.

Machinespecificatie:

| Item | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Verpakkingsnelheid | MAX 60 zakken/min, afhankelijk van de kwaliteit van de verpakkingsfilm, verpakkingsmaterialen, verpakkingsgewicht etc. | ||

| Zakformaat | (L)100-300mm (B)70-200mm | (L)100-350mm (B)130-250mm | (L)150-450mm (B)200-300mm |

| ZaktType | Voorgevormde zakken, stazak, vierzijdig gesealde zak, driezijdig gesealde zak, speciale vormzak | ||

| Weegbereik | 10g-1kg | 10g-2kg | 10g-3kg |

|

Meet nauwkeurigheid |

*≤±0.5~1%, afhankelijk van de meetapparatuur en materialen. | ||

| Maximale zak | breedte | 200mm |

250mm |

| 300mm | Gasverbruik 0.8Mpa 0.3m | ||

| 3 | Totaal | Totaal | Vermogen/Spanning |

| 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | ||

| 3.7KW 380V 50/60Hz | Niet minder dan 1CBM | Niet minder dan 1CBM | Afmeting |

| L1900*B1400*H1450 | L1900*B1400*H1450 | L2000*B1500*H1550 | Machinegewicht |

| 1300kg | 1400kg | ||

| 1500kg | Werkstroom | ||

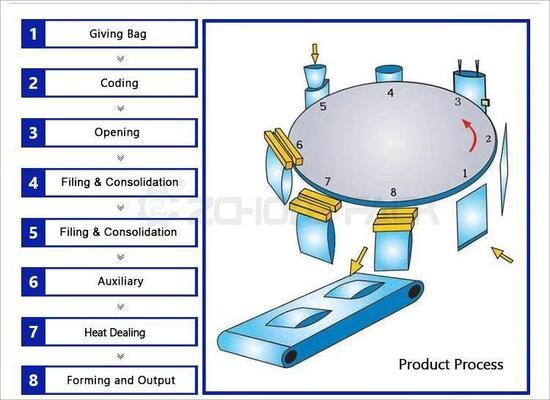

Zak geven→Coderen→Zak openen (of ritssluiting openen)→Vullen→Hulp→Uitlaat→Heat sealing→Vormen en uitvoer producten.

![]()

![]()

![]()

![]()